Additive Construction: Rethinking How We Build

At the University of Florida, our lab explores how additive construction—the 3D printing of buildings and infrastructure—can transform the way we design and construct the built environment. We focus on pushing both the scale and intelligence of 3D printing systems, aiming to make construction faster, more adaptive, and more sustainable.

One line of our work develops methods for horizontal construction of long-span concrete structures such as shells, where concrete is printed continuously along curved, elongated paths. This approach allows lightweight, architecturally expressive forms to be built efficiently without extensive formwork or scaffolding.

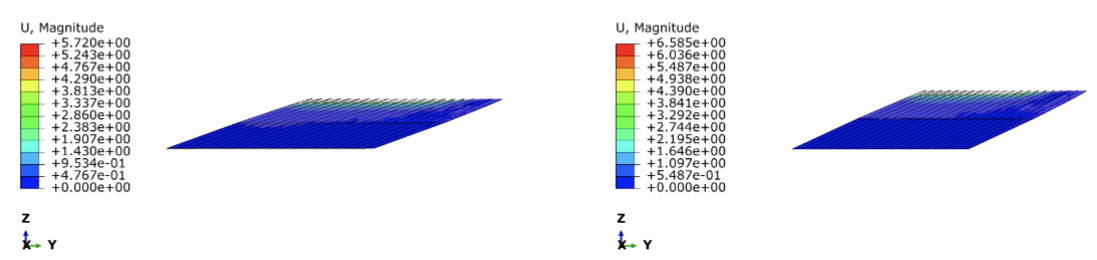

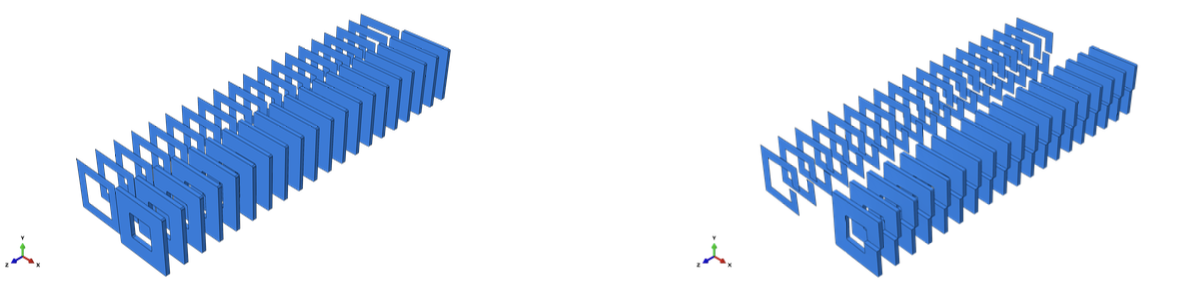

We have also developed a novel technique called linear helical printing, which produces a continuous concrete structure rather than the layer-by-layer discontinuity found in traditional 3D printing. By combining linear and rotational motion, this method enhances interlayer bonding and creates smoother, more integral printed elements.

We are also developing sensory 3D printing, embedding sensors directly into printed concrete. These embedded sensors allow the structure to “feel” its own stress, strain, and temperature in real time, opening the door to self-monitoring infrastructure.

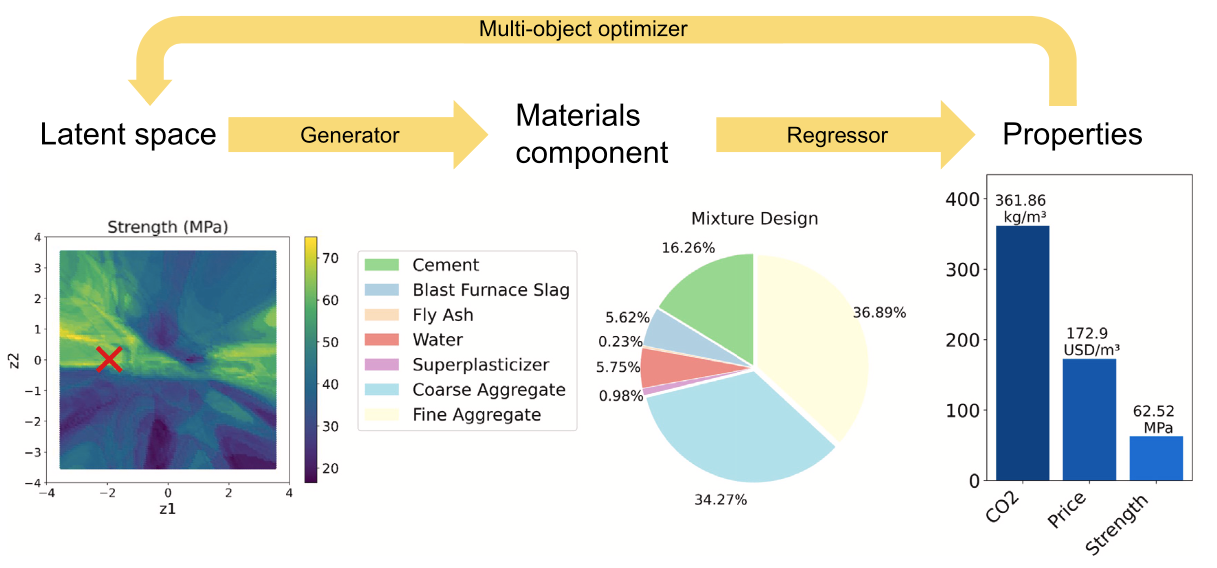

We are using artificial intelligence to optimize printable concrete materials. By learning from experimental data, AI models help us tailor mixtures for flowability, strength, and sustainability—ensuring the material is as intelligent as the printer itself.

Together, these directions point toward a future where construction is not only automated but adaptive, data-rich, and fundamentally reimagined.

···